| Model NO. | AG-019 |

| Weave Characteristic | Stamping |

| Surface Treatment | Coated |

| Stamping Expanded Metal Mesh Category | Expanded Metal Mesh |

| Galvanized Surface Treatment | Hot-galvanize |

| Hot-galvanize Technique | Line Annealing |

| Specifications | Roll |

| Weight | Light-weight |

| Transport Package | Wooden Box |

| Specification | 3.5x3.5mm |

| Origin | China |

| HS Code | 7616991000 |

| Production Capacity | 500 Rolls/Week |

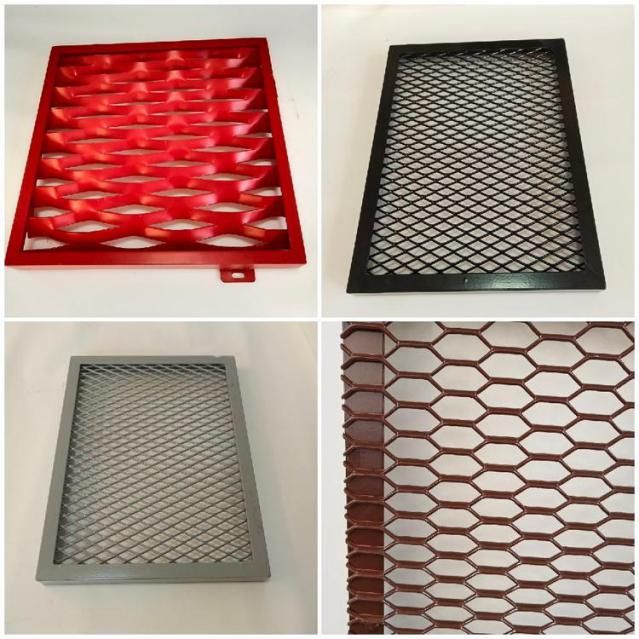

How is expanded metal made? Expanded metal Sheet is produced from metal sheet or roll through stamping and expanding, which forms a wide array of diamond shaped openings with uniform sizes. Compared with the traditional flat metal sheet, expanded metal mesh has more notable advantages for its versatile applications. Owing to the expanding process, the metal sheetcan be expanded up to 8 times its original width, losing up to 75 % its weight per meter, and becomes harder.So it is lighter, less expensive than a single metal sheet. What is expanded metal? Expanded metal mesh types includes raised expanded steel mesh (also called standard or regular expanded metal) and flat expanded metal mesh. Raised expanded metal mesh has diamond openings with slightly raised surface. Flattened expanded metal mesh is manufactured by passing the standard expanded sheet through a cold roll reducing mill, forming diamond openings with flat surface. The form of the meshes is normally rhombic but more shapes are available, such as hexagonal, oblong and rounded. The size of the meshes varies from very small meshes 6 x 3 mm suitable for filters, to very large meshes 200 x 75 mm often used for architectural applications. The materials most often utilised for expanded metal are mild steel, aluminium and stainless steel, but we also offer in other materials (brass, copper, titanium, zinc, etc). The length and width of the sheet and the grid parameters are always described according to the following pictures.

How is expanded metal made? Expanded metal Sheet is produced from metal sheet or roll through stamping and expanding, which forms a wide array of diamond shaped openings with uniform sizes. Compared with the traditional flat metal sheet, expanded metal mesh has more notable advantages for its versatile applications. Owing to the expanding process, the metal sheetcan be expanded up to 8 times its original width, losing up to 75 % its weight per meter, and becomes harder.So it is lighter, less expensive than a single metal sheet. What is expanded metal? Expanded metal mesh types includes raised expanded steel mesh (also called standard or regular expanded metal) and flat expanded metal mesh. Raised expanded metal mesh has diamond openings with slightly raised surface. Flattened expanded metal mesh is manufactured by passing the standard expanded sheet through a cold roll reducing mill, forming diamond openings with flat surface. The form of the meshes is normally rhombic but more shapes are available, such as hexagonal, oblong and rounded. The size of the meshes varies from very small meshes 6 x 3 mm suitable for filters, to very large meshes 200 x 75 mm often used for architectural applications. The materials most often utilised for expanded metal are mild steel, aluminium and stainless steel, but we also offer in other materials (brass, copper, titanium, zinc, etc). The length and width of the sheet and the grid parameters are always described according to the following pictures.

Packaging steps: Each piece put in on carton box, wood case, Plastics Packaging, pallet, etc. Mode of shipping: Shipping by air, sea or car. By sea for batch goods; Customs specifying freight forwarders or negotiable shipping methods.

Packaging steps: Each piece put in on carton box, wood case, Plastics Packaging, pallet, etc. Mode of shipping: Shipping by air, sea or car. By sea for batch goods; Customs specifying freight forwarders or negotiable shipping methods. The different types of meshes have different degrees of strength since the open area and weight of each type can vary substantially. Below we have listed examples of the many situations where expanded Metal can be used with advantage. The high strength and the anti-skid qualities make expanded metal most advantageous for: Walkways Footbridges Footsteps Ramps Platforms and similar applications. Expanded metal can also make an effective barrier and is favourable for use in security/safety applications to protect e.g. buildings, people or machines. Expanded metal also achieves a sound reduction and shielding effect, ideal for use in airports and bus stops. Expanded metal is a very popular material for today's architectural and industrial design and our many customers all over the world use it for many other applications apart from those mentioned above. Building / Architecture Examples of applications in buildings where the use of expanded metal will be a benefit: Cladding Ceilings Facades Sun protection Fencing Shielding For these applications the expanded metal most commenly used has a rib width larger than 20 mm. Expanded metal can also be used for reinforcing concrete, plastic, artificial materials or for acoustic panels. It also works well as a decorative product where there is a requirement for a coarse appearance.

The different types of meshes have different degrees of strength since the open area and weight of each type can vary substantially. Below we have listed examples of the many situations where expanded Metal can be used with advantage. The high strength and the anti-skid qualities make expanded metal most advantageous for: Walkways Footbridges Footsteps Ramps Platforms and similar applications. Expanded metal can also make an effective barrier and is favourable for use in security/safety applications to protect e.g. buildings, people or machines. Expanded metal also achieves a sound reduction and shielding effect, ideal for use in airports and bus stops. Expanded metal is a very popular material for today's architectural and industrial design and our many customers all over the world use it for many other applications apart from those mentioned above. Building / Architecture Examples of applications in buildings where the use of expanded metal will be a benefit: Cladding Ceilings Facades Sun protection Fencing Shielding For these applications the expanded metal most commenly used has a rib width larger than 20 mm. Expanded metal can also be used for reinforcing concrete, plastic, artificial materials or for acoustic panels. It also works well as a decorative product where there is a requirement for a coarse appearance.

Feel free to contact us for more information and let us find the right solution to your needs.

Feel free to contact us for more information and let us find the right solution to your needs.

Examples of applications in the agricultural and industrial sectors where the use of expanded metal will be beneficial: Filtration Ventilation Laminated metal for draining floors for farm buildings Floors in containers Heat exchangers for several applications to hold the tubes Earthing of electricity Walkways for cranes Protection / shielding in front of dangerous elements

Examples of applications in the agricultural and industrial sectors where the use of expanded metal will be beneficial: Filtration Ventilation Laminated metal for draining floors for farm buildings Floors in containers Heat exchangers for several applications to hold the tubes Earthing of electricity Walkways for cranes Protection / shielding in front of dangerous elements